Klucz do zintegrowanych rozwiązań systemowych

Komponenty elektryczne odpowiadają za rosnącą liczbę zadań w napędach silników spalinowych. Działają niezależnie od silnika spalinowego, odciążając go, co zasadniczo zwiększa wydajność napędu w obrębie całego systemu.

Pierwszym krokiem do elektryfikacji jest zastąpienie siłowników hydraulicznych i pneumatycznych siłownikami elektrycznymi. W związku z tym, że umożliwiają one szybszą, bardziej precyzyjną kontrolę, siłowniki elektryczne poprawiają m in. spalanie, ograniczając przez to zużycie paliwa oraz emisje.

W drugim kroku, MAHLE uzbraja akcesoria silnikowe w “inteligencję”: wyposażone w silnik elektryczny, akcesoria silnikowe mogą działać niezależnie od prędkości oraz ciśnienia silnika. Mogą być przez to zaprojektowane w oparciu o określone zapotrzebowanie, zapewniając przy tym niebywałą precyzję. Wspierają również funkcje stop-start w silniku spalinowym i mogą być zasilane przez energię uzyskaną podczas faz hamowania.

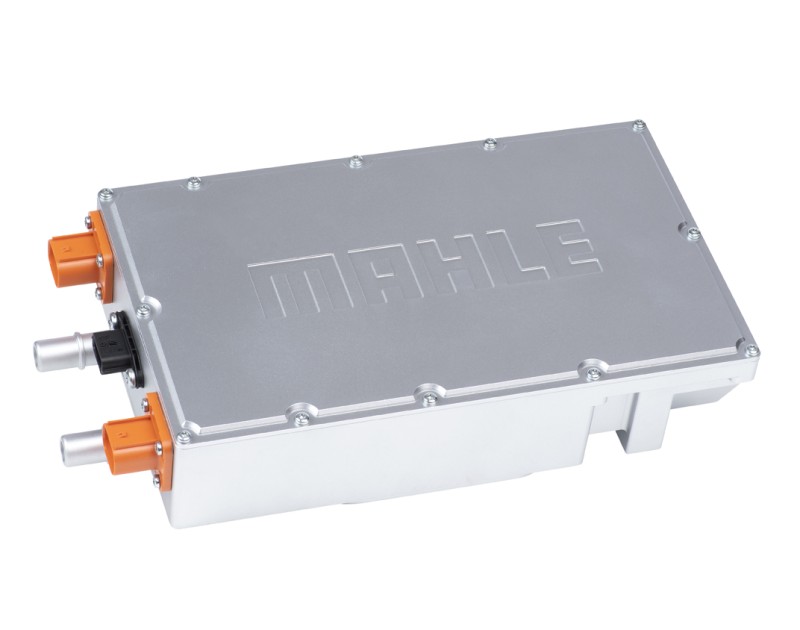

Low Voltage Traction Inverter

Low Voltage Traction Inverter from MAHLE are designed for battery voltage from 24 up to 80 V, with special focus on 48 V applications. Together with the sophisticated software and integrated CANOpen protocol, they offer considerable adjustability, dynamic behavior and high efficiency of the drive system. Their reliable design with state-of-the-art MOSFET devices result in very low EMC emissions and a high power density. Funcional Safety features (ISO 13849 / ISO 26262) are available on request to fulfill customers’ specific requirements.

Energy Management

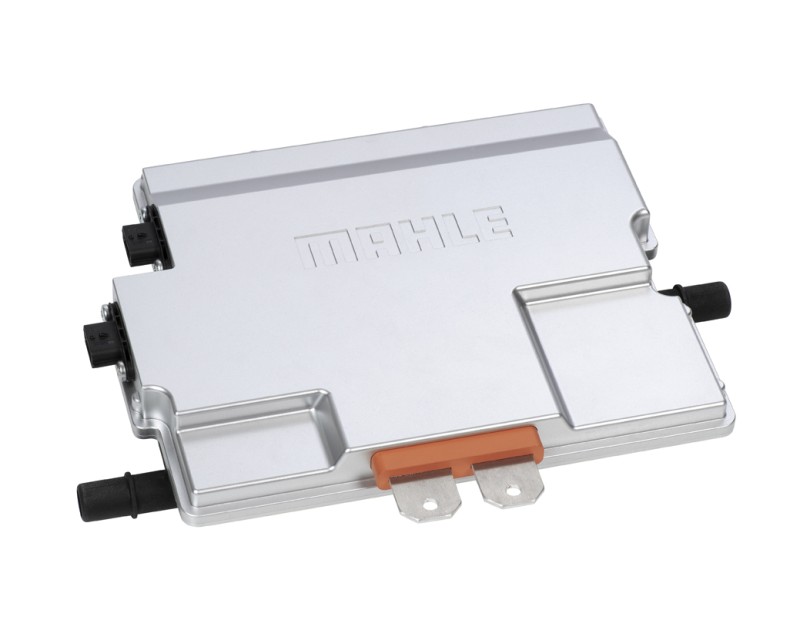

On-Board Charger

Electronic on-board charging systems from MAHLE installed in the vehicle ensure a high level of safety and efficiency during the charging process. The intelligent controller detects the type of charging system, so that the charging parameters can be optimally adapted to the conditions of the infrastructure. The compact module opens up the possibility of flexible use of a large number of different charging stations, from relatively slow, single-phase charging from a household outlet to fast direct-current charging concepts rated at 43 kilowatts. Continuous monitoring of temperatures, grounding, and potential creep currents guarantees high operational safety.

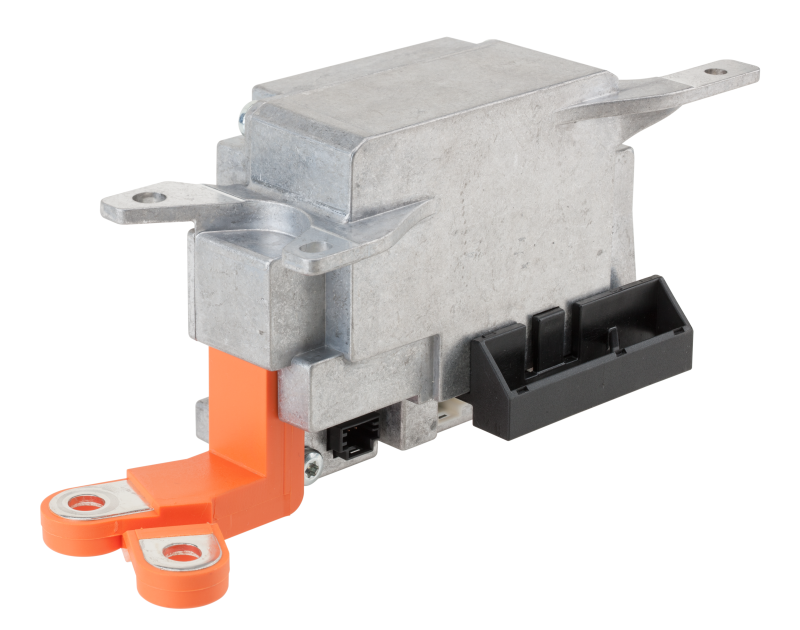

EMC Battery Filter

MAHLE EMC Battery Filters are designed to effectively reduce EMC interference of batteries with 400 V and up to 190 A nominal current. With a filter bandwidth of 150 kHz to 300 MHz the filters realize maximum insertion loses of 60 dB at a frequency of 1 MHz. They improve the immunity of the HV battery from the high voltage vehicle transients and comply with rigorous automotive standards while maintaining their compact and robust design. Our custom designs guarantee a perfect fit to the battery impedance and the clients’ requirements.

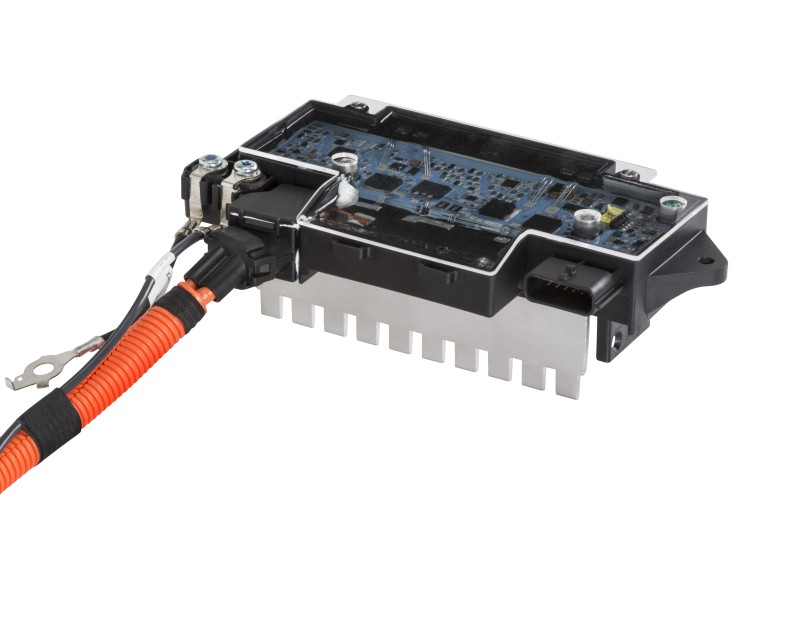

DC-DC Converter

DC to DC step-down isolated voltage converters are the link between the high-voltage (HV) drive train battery and the existing 12-volt low-voltage system. These DC-DC converters not only have to ensure high reliability in the car, they also need to score with efficiency and high power density. Based on specialized components developed in-house, MAHLE offers systems solutions that can be used both as a stand-alone unit and as a module in integrated concepts, covering a voltage range.

Fuel Cell Monitor

With Fuel Cell Monitors from MAHLE it is able to control the status of the hydrogen fuel cell stack including voltage, impedance and temperature. Equipped with two microprocessors that process the signals from the fuel cell stack and provide feedback to the central control unit it is able to fulfill all required functional safety requirements. When required, the voltage in the stack can be discharged directly via a semiconductor module. To guarantee maximum safety pyro-switches are employed, that can instantly cut the power connection in case of emergency.

Power Electronics for Auxiliaries

Motor Controller

Motor controllers from MAHLE are intended for the operation of brushed and brushless DC motors in various automotive applications. From control units for air conditioning blowers, controllers for electric pumps to control units for power train cooling fan motors, MAHLE can offer the right solution. The controllers are characterized by their compact and lightweight dimensions, cost efficiency and their customer-specific design. Regardless of whether as a PWM or linear controller, whether communication protocols need to be integrated or additional functions such as over-temperature, over-voltage, or reverse polarity protection are required, MAHLE offers the best suitable possible solution for the specific customer requirements.

PTC Heater Controller

PTC heater controllers are used to manage air heating or coolant heating in the HVAC through PWM technology. They are available from low voltages (12 & 48 V) to high voltages (400 & 800 V) within a power range of 500 to 2700 watts for low voltages and 4000 to 8000 watts for high voltage, and different communication protocols (PWM, LIN, CAN...). With our new product generations, we optimize thermal behavior to achieve excellent power density enabling HVAC integration in challenging volumes.

Electronics for Diesel Systems

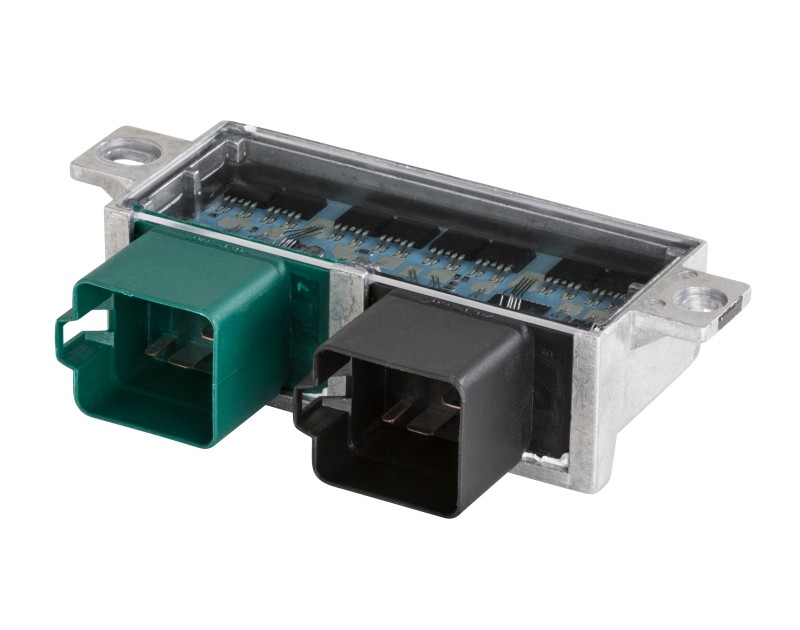

Glow control units for diesel engines

Glow control units support the starting process of diesel engines at cold temperatures. They enable better combustion of the diesel-fuel mixture and are designed for glow plugs with a voltage of 4.4 V, which reach their full glow temperature much faster. MAHLE systems can control up to four glow plugs independently of each other and are protected against short circuits and overheating. This makes the glow control units particularly robust and reliable. The systems are designed for an operating voltage of 6 to 16 volts and allow flexible positioning in the engine compartment thanks to a wide temperature range from -40 to +90 °C.

Exhaust aftertreatment for diesel engines

Today, exhaust aftertreatment systems are an important component of the overall engine system for further reducing pollutant emissions. In order to achieve the operating temperatures required for cleaning diesel particulate filters even in short-distance operation, MAHLE develops control units that take over the temperature management of the system. This is done, for example, by briefly increasing the engine power in idle mode, so that more hot exhaust gases reach the filter, inject chemical substances to promote particle combustion, or increase the temperature in the exhaust tract through fuel injection or electric heaters in the exhaust tract. In addition to the electrical controls, MAHLE also supplies the sensor elements required for particle filter management.