Bringing the street into the lab

MAHLE climatic wind tunnel

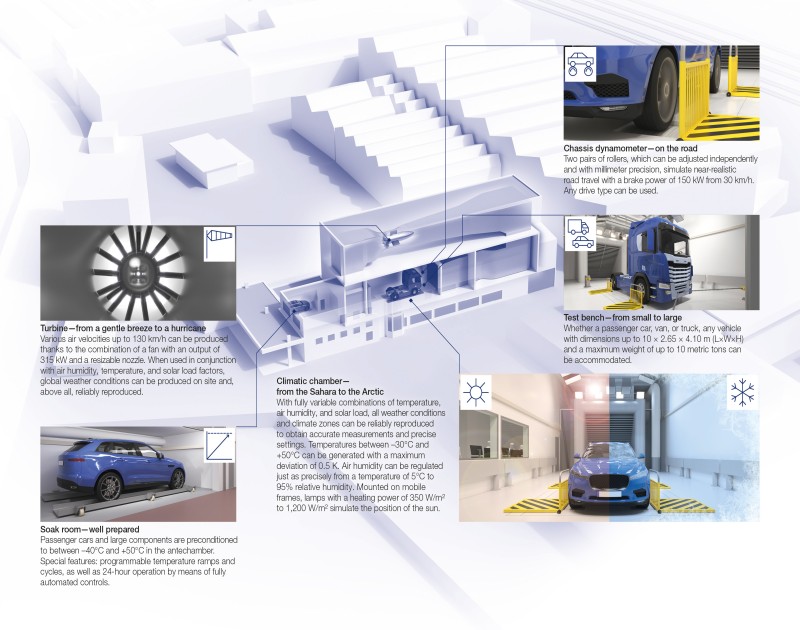

Since 1936, we have been employing wind tunnels in the development of thermal management solutions for passenger cars, commercial vehicles, and off-highway applications.

As the leading international OEM of vehicle air conditioning and engine cooling systems, we not only invest in research and development of our own products, but also provide our customers with comprehensive development services.

Our climatic wind tunnels in Stuttgart/Germany and Troy, Michigan/USA provide realistic conditions for measurement and testing without elaborate road testing. They provide a reliable basis for a smooth technology transfer, quality management, cost reduction, and time savings—all in the interest of our customers.

play