Global climate change means that we need to rethink things- including the way our mobility looks.

Indeed, every single component that the automotive industry develops today can impact the climate of the future. Good solutions today are therefore also the better ones for tomorrow. And the Paris Agreement in 2015 made it official: the world of tomorrow needs us to limit the global temperature rise to below two degrees Celsius. This is a daunting undertaking that calls for effective cooperation on the part of every stakeholder in public policy, science, economy, and industry. And a task that can be accomplished primarily through one avenue: by reducing anthropogenic carbon dioxide (CO2).

E-mobility will be a key component if the mobility of the future is to be sustainable. Yet even the combustion engine has its place in such a future. According to current predictions, global vehicle production will continue to grow and the demand for components and systems for combustion engines will also further increase along with it. This is due in part to the countless regions of the world lacking important basic conditions, such as a comprehensive power grid, that are required for e-mobility to successfully gain a foothold. On the other hand, the combustion engine is still justified as an efficient solution in the long-haul commercial vehicle sector.

U AS IN UNIQUE IMPACT

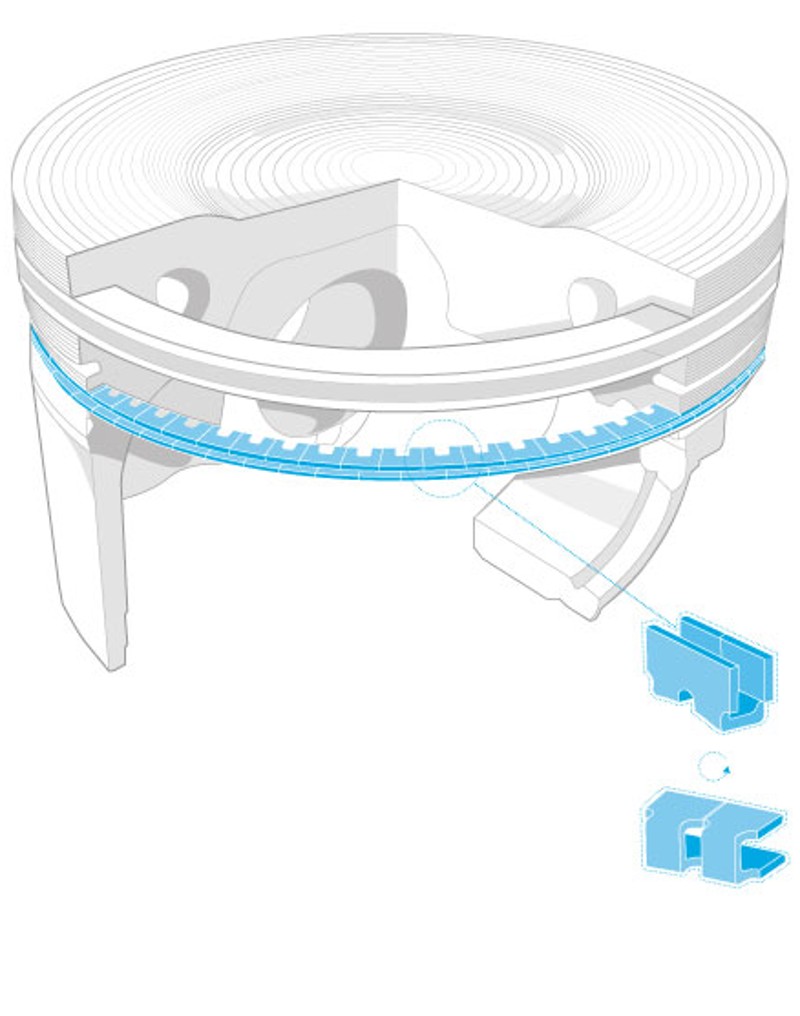

These arguments are also part of the reason why MAHLE remains convinced of the combustion engine’s viability and continues to optimize it. An intelligent mix of vehicles with conventional and alternative drives will be a crucial factor and can play a key role in achieving climate targets. With regard to the combustion engine, CO2 emissions could be reduced by up to 10 percent per vehicle in the next three to five years by means of MAHLE components alone. What will make this reduction possible in part is a small black ring. Seemingly unimposing at first glance, in reality it is a high-tech product with a big impact: the MAHLE U-flex Generation 1 (Gen.1) oil control ring helps to significantly lower CO2 and particulate emissions in vehicles, thereby promoting cleaner air and quality of life. For people and the environment.

A healthy climate and clean air for everyone—the goal seems simple.

But achieving it is a challenge that calls for innovative ideas and sophisticated technologies. MAHLE has accepted this challenge. Our solution is in the detail—in the truest sense of the word. The latest generation of the MAHLE U-flex ring shows that even a small component, seemingly unimportant at first glance, can be the spark that ignites a major change for the world: by lowering carbon dioxide emissions and providing cleaner air, thereby significantly improving people’s quality of life.

DID U KNOW?

The advantages of the U-flex are even greater in vehicles that run on natural gas (CNG): CNG combustion does not involve particulate matter. The particulate emissions in the exhaust gas come entirely from combusted engine oil. The U-flex ring Gen.1 works so efficiently that the CNG engine can be operated without a particulate filter while maintaining compliance with the strictest thresholds—yet another cost advantage for the driver.

Trying everything possible to achieve the impossible

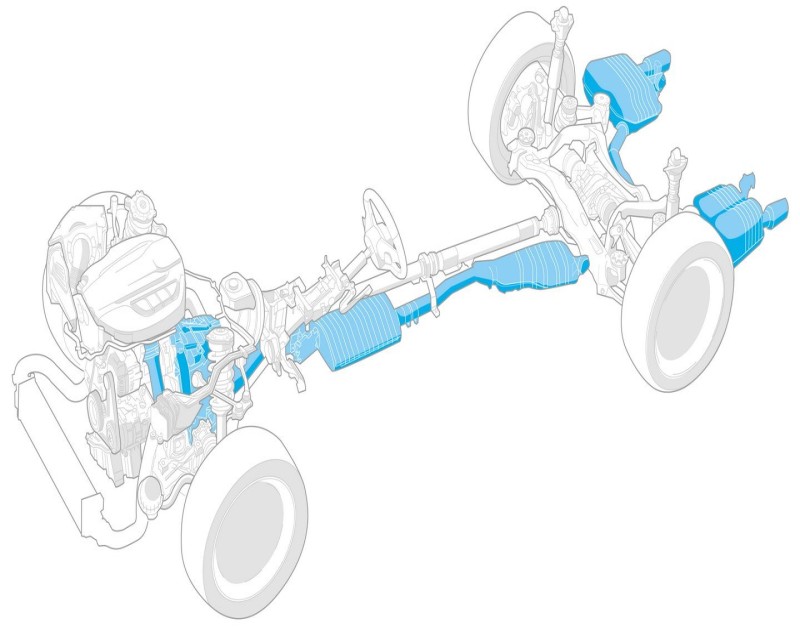

When the conversation turns to change in the automotive industry, the term “e-mobility” is often mentioned in the same breath. When a young company on the Californian coast was missing a crucial assembly for its electric vehicle, it launched a tender. This called for a concept that MAHLE had already applied in a similar way. So far, so good.

But the major challenge was to supply the customer with the desired, specific solution based on this concept within 13 months. The norm for product development of this scale is usually 24 months. This would be a risk for any supplier that doesn’t make compromises in its development and production. But MAHLE accepted the challenge. An international team of experts from the USA, Germany, Japan, and Mexico was assembled. Over 13 months, it proved—across time zones and despite the shortage of time—that, however difficult it may appear to be, MAHLE is ready to make any customer idea possible. And, above all, ready to deliver an outstanding product.

RUEIL-MALMAISON

Remi Rabute

»You wouldn’t know it by looking at this small, simple ring, but because it’s so effective, we can use U-flex to save thousands of liters of oil today and in the future.«

STUTTGART

Jochen Adelmann

»Primarily in Europe, we are confronted with increasingly strict public policy requirements regulating pollutant emissions. For us, there is no doubt that the combustion engine is a tried-and-tested technology that has a particular role to play in a more sustainable mobility. With solutions such as U-flex Gen.1 we significantly improve the emissions footprint of the combustion engine.«

JUNDIAÍ

Rafael Antonio Bruno

»U-flex is based on a tried-and-tested concept that is proving to be an important, relevant product for our time following our reengineering of Gen.1: a piston ring that helps to make the air better for us all.«

MURTEDE

Luis Sobral

»Our aim with U-flex Gen.1 is to help our customers respond to the tremendous challenges posed by industry, public policy, and society with regard to climate protection.«